paddy

Active member

Hello,

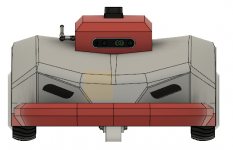

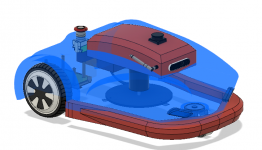

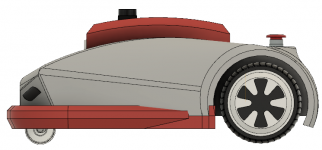

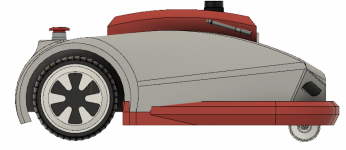

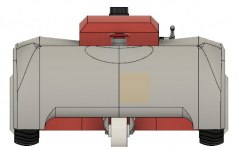

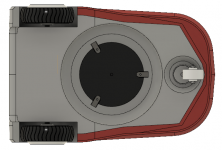

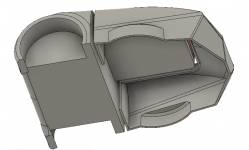

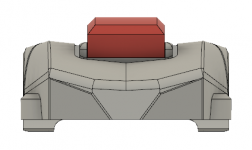

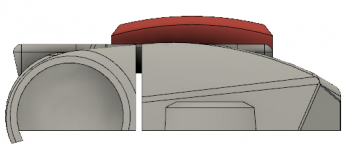

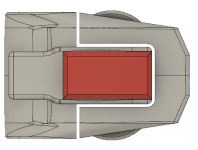

back in 2018, I tried to build a partly 3D printed lawn mower https://forum.ardumower.de/threads/paddys-mower.23026/. But because Robin Fröjd started an even cooler, 3D printed lawn mower, I retired my build for his great design and was satisfied so far.

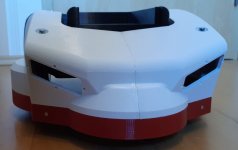

But I wanted to try new things. It should be more silent and it should be based on ROS, Robot Operation System. Just I wanted to learn something new.

On the other hand, I don't want to spend 1000€plus in a DIY lawn mower. Sadly, BLDC motors are expensive as we all now. In the end, I found an alternative which you can get for mostly nothing (I payed 20€): Hoverboards

These toys are equipped with a 36V battery, a motor driver based on STM32 and two really powerful BLDC hub motors. They're capable to handle 150kg and drive really fast. But they can also run pretty slow.

After digging around, I found some other people using these motors together with ROS. Time to re-born this old build.

It runs on ROS Noetic on a Raspberry PI 3b+, which is connected to a PS4 controller by Bluetooth and to Hoverbard PCB by UART. It is incredible how powerful these motors are and especially, how silent. Odometry works as well. Next step will be implementing a ROS node for Ardumower perimeter fence and to re-build Ardumower functionality in ROS.

back in 2018, I tried to build a partly 3D printed lawn mower https://forum.ardumower.de/threads/paddys-mower.23026/. But because Robin Fröjd started an even cooler, 3D printed lawn mower, I retired my build for his great design and was satisfied so far.

But I wanted to try new things. It should be more silent and it should be based on ROS, Robot Operation System. Just I wanted to learn something new.

On the other hand, I don't want to spend 1000€plus in a DIY lawn mower. Sadly, BLDC motors are expensive as we all now. In the end, I found an alternative which you can get for mostly nothing (I payed 20€): Hoverboards

These toys are equipped with a 36V battery, a motor driver based on STM32 and two really powerful BLDC hub motors. They're capable to handle 150kg and drive really fast. But they can also run pretty slow.

After digging around, I found some other people using these motors together with ROS. Time to re-born this old build.

It runs on ROS Noetic on a Raspberry PI 3b+, which is connected to a PS4 controller by Bluetooth and to Hoverbard PCB by UART. It is incredible how powerful these motors are and especially, how silent. Odometry works as well. Next step will be implementing a ROS node for Ardumower perimeter fence and to re-build Ardumower functionality in ROS.