Bin heute den halben Nachmittag im Garten gewesen und habe eine 2. Perimeterschleife provisorisch abgesteckt (25,4 Ohm, 12V / 0,84A). Perimetertracking mit factory default-Parametern für PID funktioniert, aber der Robbi schwänzelt schon ganz schön hin und her.

Gibt es andere Ardumower-Fans, die die DENNA-Plattform benutzen?

Wenn ja, was habt Ihr an den Standard-Parametern geändert?

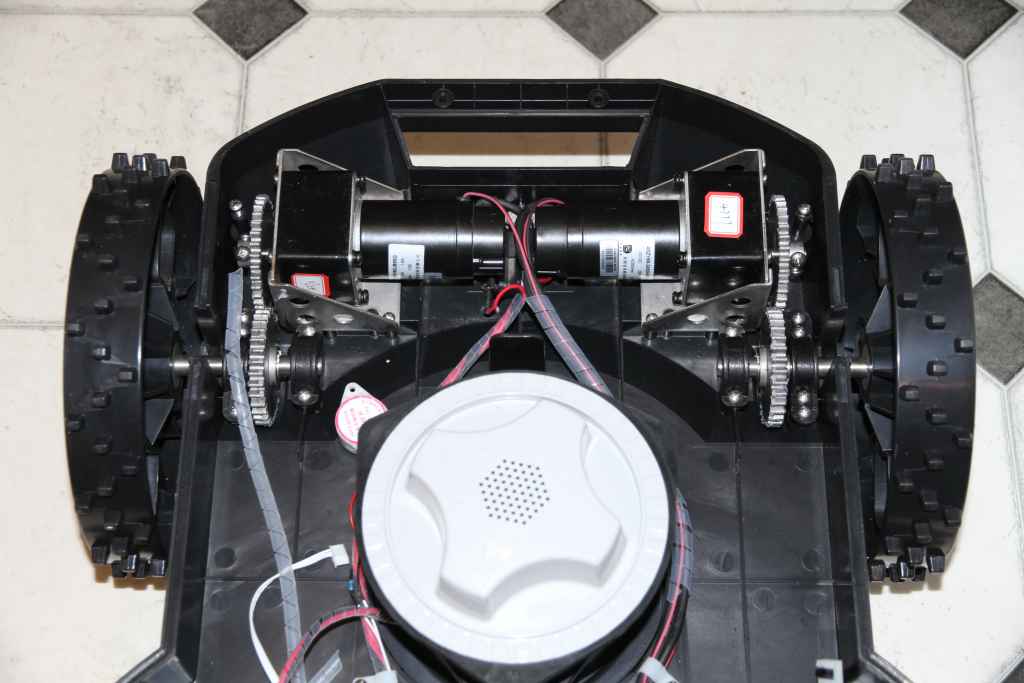

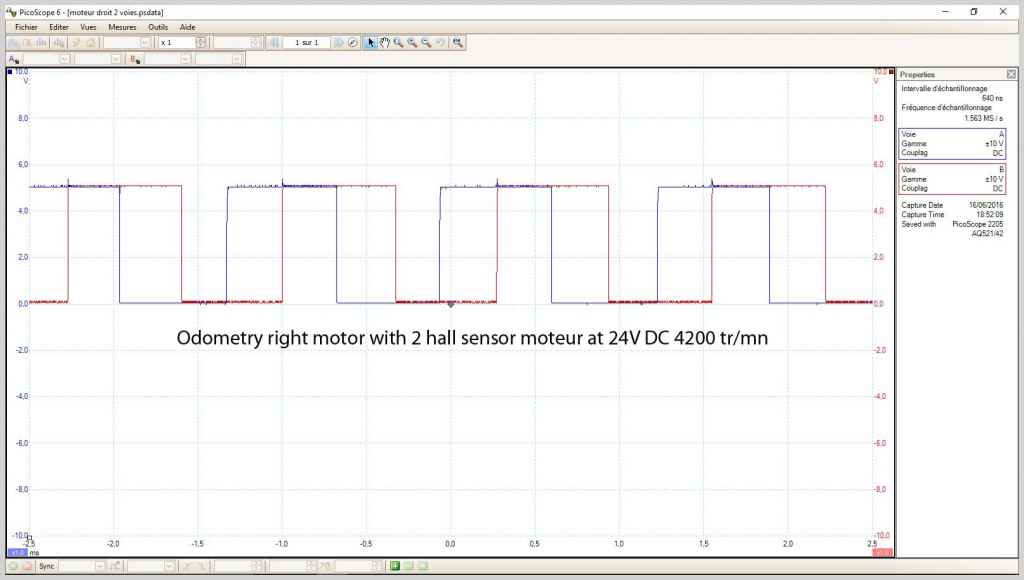

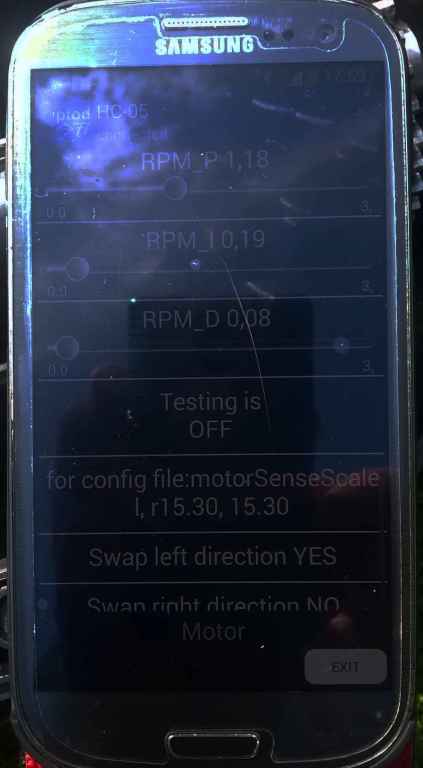

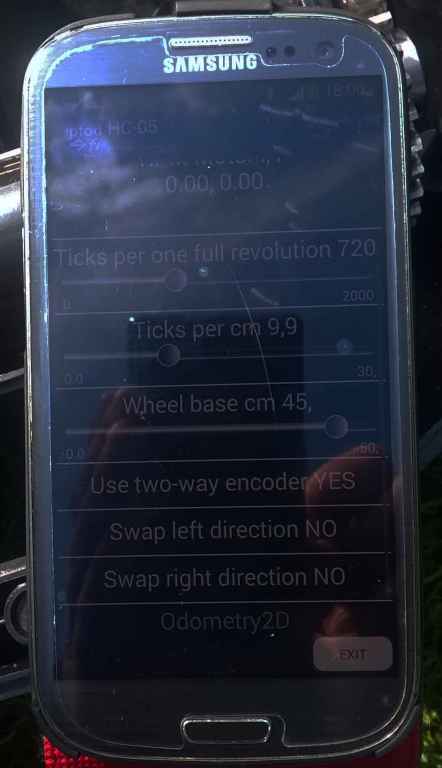

Ich werde hier jedenfalls nach und nach hier meine DENNA RML-100 Spezifika einstellen ...

Gruß ... Peter

Gibt es andere Ardumower-Fans, die die DENNA-Plattform benutzen?

Wenn ja, was habt Ihr an den Standard-Parametern geändert?

Ich werde hier jedenfalls nach und nach hier meine DENNA RML-100 Spezifika einstellen ...

Gruß ... Peter