So the motor setting is perfect.That is the only small hill on my ground, the rest is flat and straight.

I need to change the factory setting (value -88 and -92 are inverted in the lane 2) but it's better to do this in real mowing condition.

So the motor setting is perfect.That is the only small hill on my ground, the rest is flat and straight.

@RonPeeters @bernard @Starsurfer78

my Fork of Azuritber: https://github.com/Lichte12/AzuritBer/tree/working (Working Branch)

WebControl for Azuritber (For ESP8266 and without Trends): https://github.com/Lichte12/MowerWebControl_AzuritBer

I think there is also a code for the ESP32 Webinterface in this Forum.

Only the html files in the data folder have to be changed for Azurit, Azuritber or somthing else.

C:\Users\sefan\Desktop\Arduino\MowerWebControl_AzuritBer-main\MowerWebControl_ESP8266\MowerWebControl_ESP8266.ino: In function 'bool handleFileRead(String)':

MowerWebControl_ESP8266:554:42: error: 'getContentType' is not a member of 'esp8266webserver'; did you mean 'mime::getContentType'?

554 | String contentType = esp8266webserver::getContentType(path);

| ^~~~~~~~~~~~~~

In file included from C:\Users\sefan\Documents\ArduinoData\packages\esp8266\hardware\esp8266\3.0.1\libraries\ESP8266WebServer\src/ESP8266WebServer.h:32,

from C:\Users\sefan\Desktop\Arduino\MowerWebControl_AzuritBer-main\MowerWebControl_ESP8266\MowerWebControl_ESP8266.ino:2:

C:\Users\sefan\Documents\ArduinoData\packages\esp8266\hardware\esp8266\3.0.1\libraries\ESP8266WebServer\src/detail/mimetable.h:49:8: note: 'mime::getContentType' declared here

49 | String getContentType(const String& path);

| ^~~~~~~~~~~~~~

Bibliothek ESP8266WiFi in Version 1.0 im Ordner: C:\Users\sefan\Documents\ArduinoData\packages\esp8266\hardware\esp8266\3.0.1\libraries\ESP8266WiFi wird verwendet

Bibliothek ESP8266WebServer in Version 1.0 im Ordner: C:\Users\sefan\Documents\ArduinoData\packages\esp8266\hardware\esp8266\3.0.1\libraries\ESP8266WebServer wird verwendet

Bibliothek Ticker in Version 1.0 im Ordner: C:\Users\sefan\Documents\ArduinoData\packages\esp8266\hardware\esp8266\3.0.1\libraries\Ticker wird verwendet

exit status 1

'getContentType' is not a member of 'esp8266webserver'; did you mean 'mime::getContentType'?

The wire mowing ist ok, but in lane mowing mode, the mower switched after a few minutes into the random mode. I'll try to have a look at the console output.@SefanH :

The Arduremote console need to be open to see the message (It's only real time data ,nothing is recorded) using a PI is the solution for this and web interface.

A motor powermax generate what you see mower stop the wire mowing.

Certainly try to increase a little drive motor power max or check the console during the wire mowing.

For IMU maybe you can test to connect the IMU at I2C6 connector (do not forget the jumper) No pullup resistor on PCB1.3 at this location.

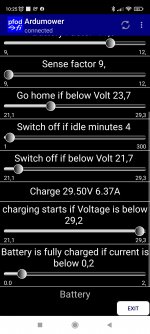

sendSlider("j08", F("Sense factor"), robot->batSenseFactor, "", 0.01,2, 1); double accel = 0.05;

if (abs(batVoltage - batvolt) > 8) batVoltage = batvolt; else batVoltage = (1.0 - accel) * batVoltage + accel * batvolt;

if (abs(chgVoltage - chgvolt) > 8) chgVoltage = chgvolt; else chgVoltage = (1.0 - accel) * chgVoltage + accel * chgvolt;

if (abs(chgCurrent - curramp) > 0.4) chgCurrent = curramp; else chgCurrent = (1.0 - accel) * chgCurrent + accel * curramp; //Deaktiviert für Ladestromsensor berechnung//#define PWM_FREQUENCY 3900

//#define TC_FREQUENCY 3900

#define PWM_FREQUENCY 10000

#define TC_FREQUENCY 10000