Arctic Hare mod printing and building thread.

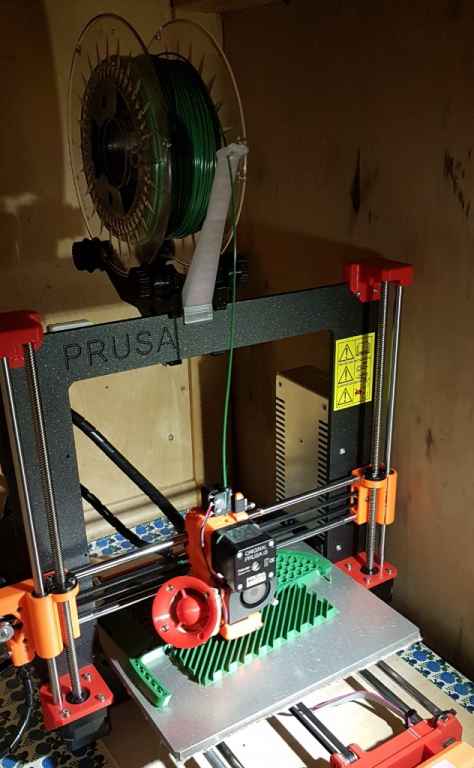

Some progress has been made. Electronics kit has not arrived yet.

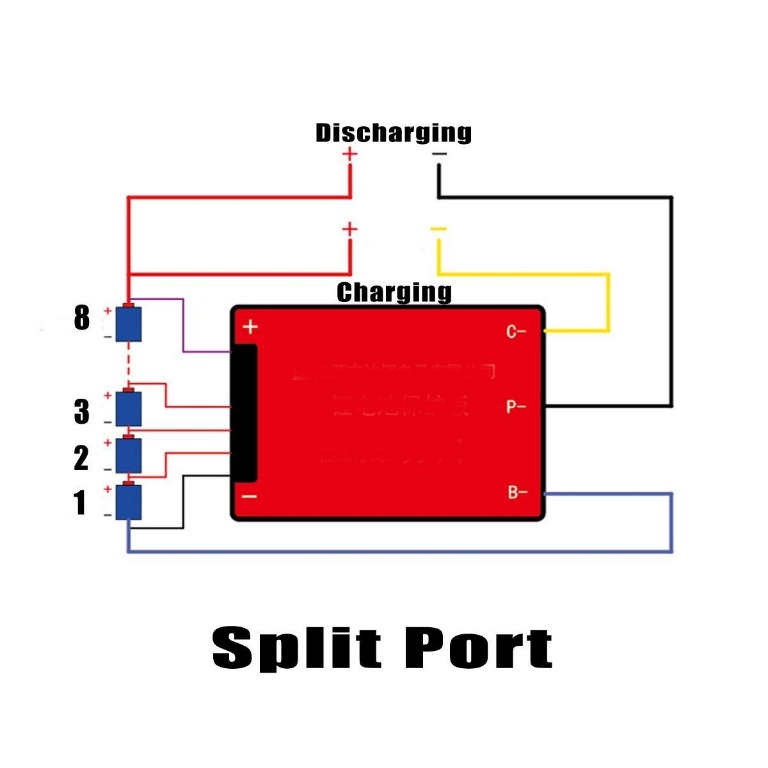

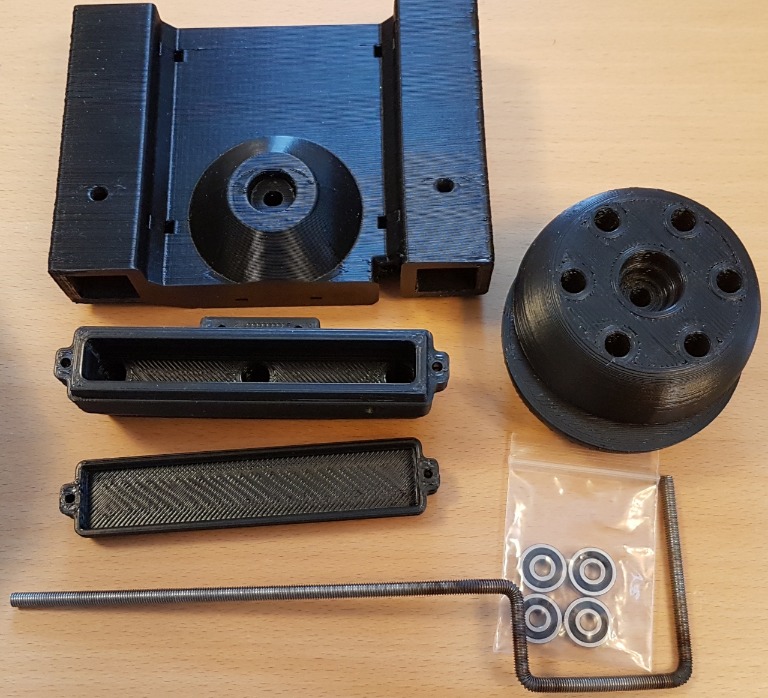

Battery box and NESE modules for 18650 cells. Plan is use samsung 35E 3500mAh cells (3p7s)

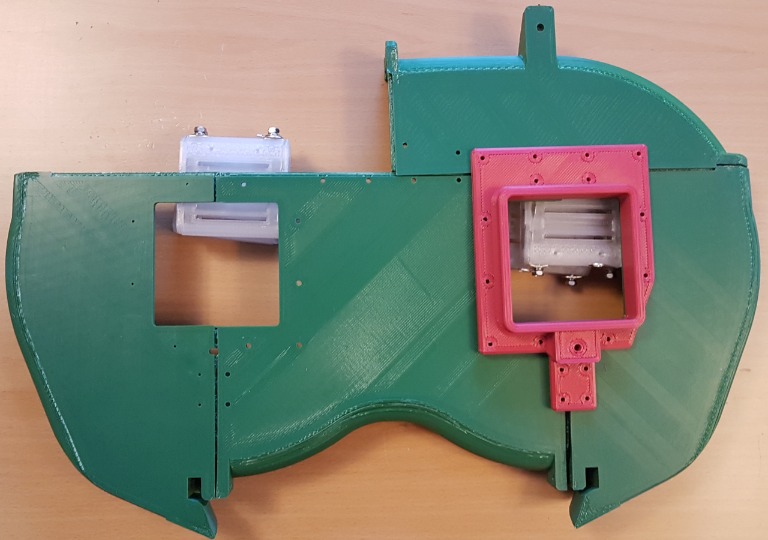

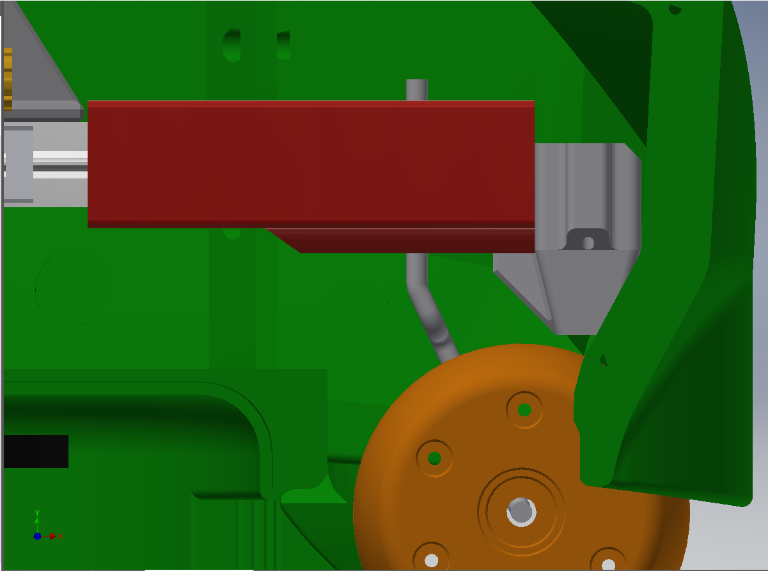

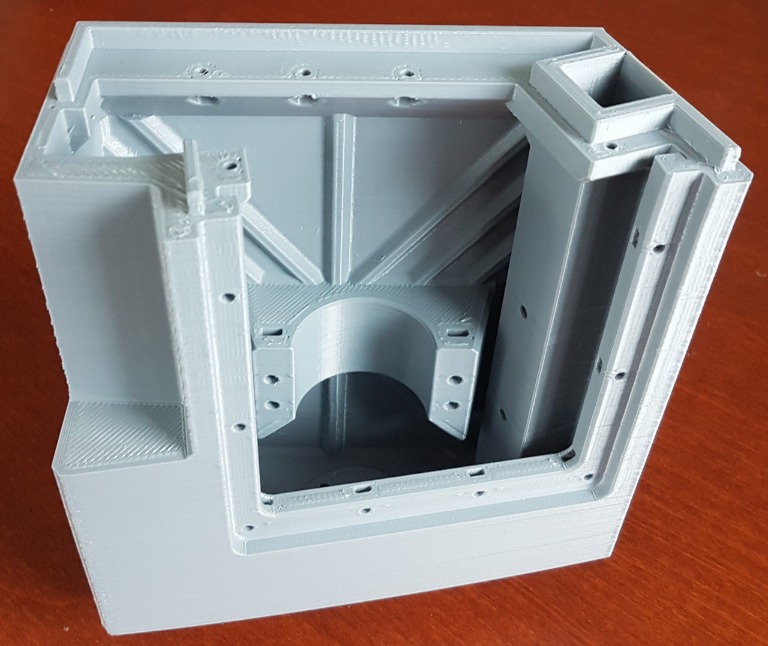

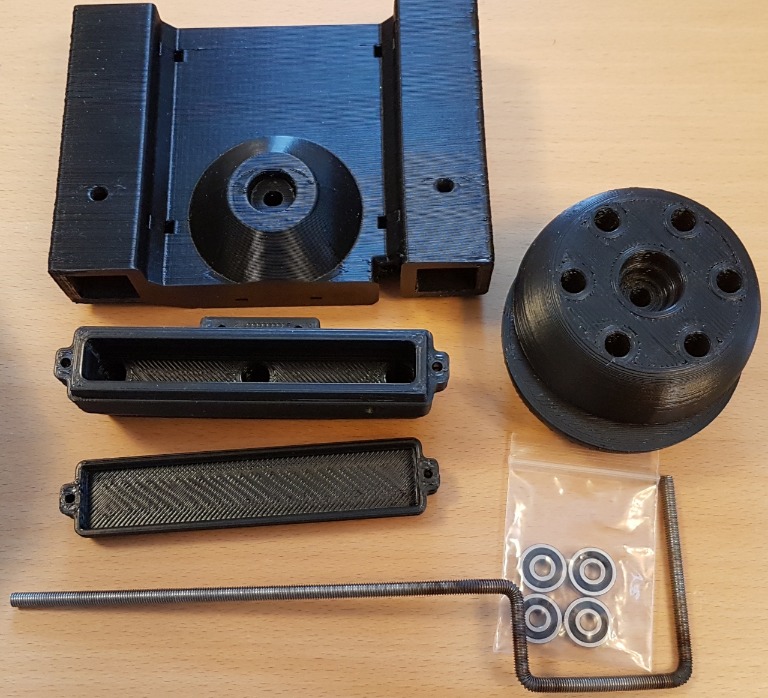

Front wheel assembly and perimeter receiver box

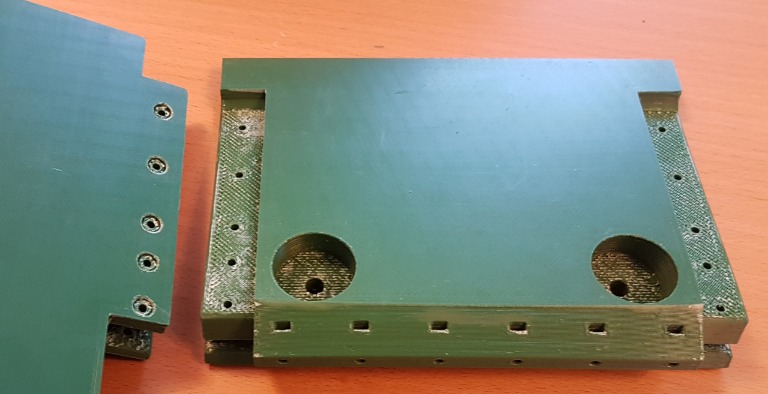

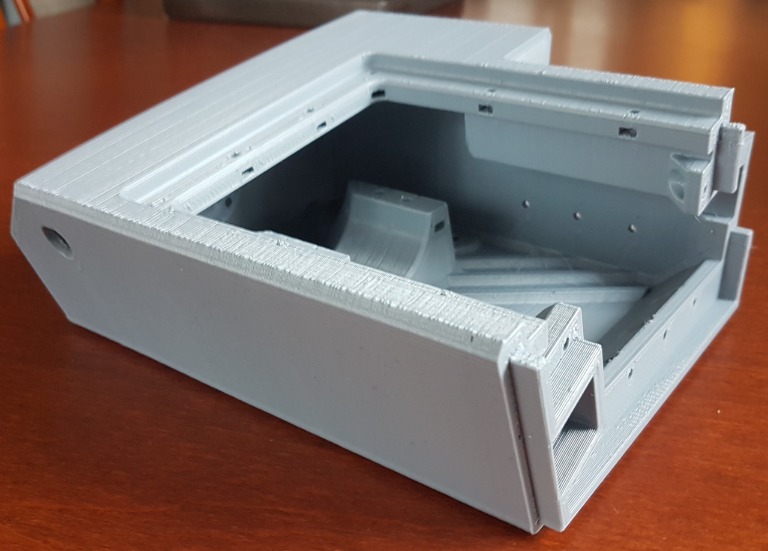

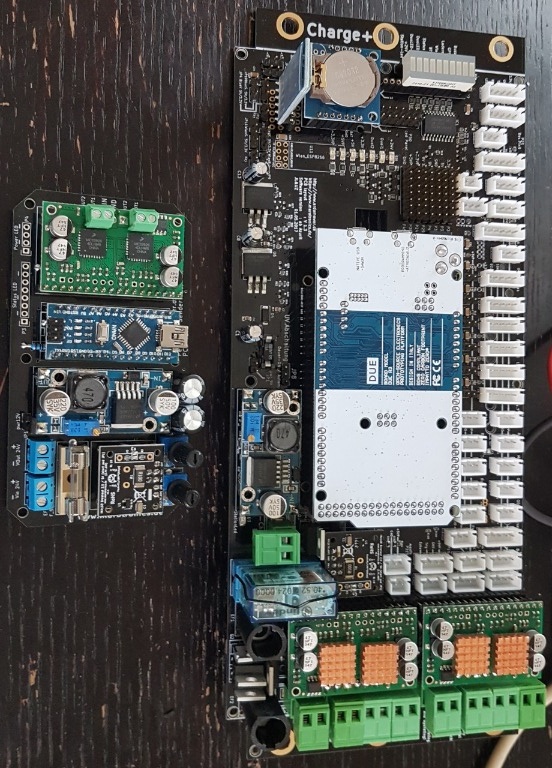

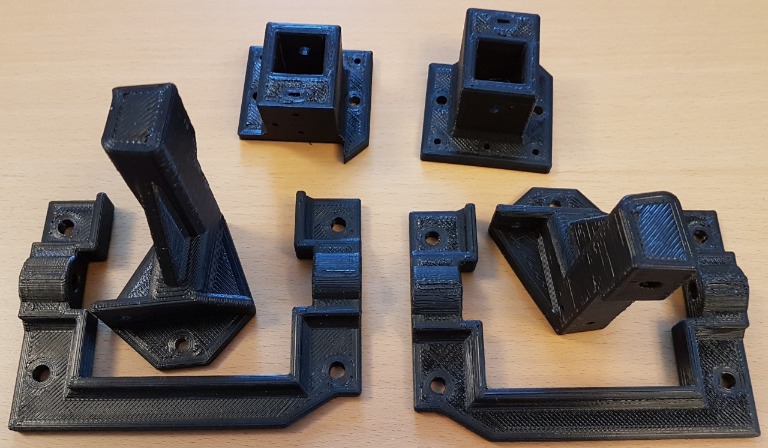

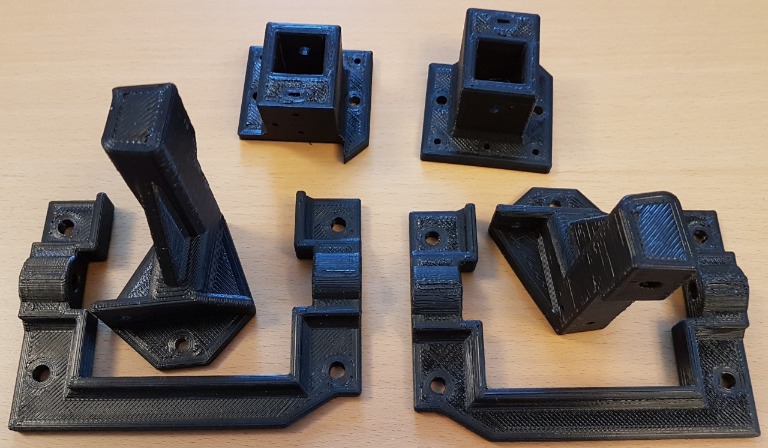

pcb box brackets and mowing motor brackets

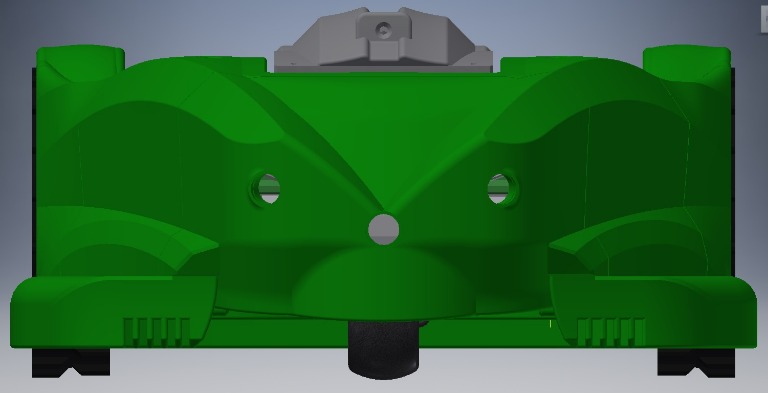

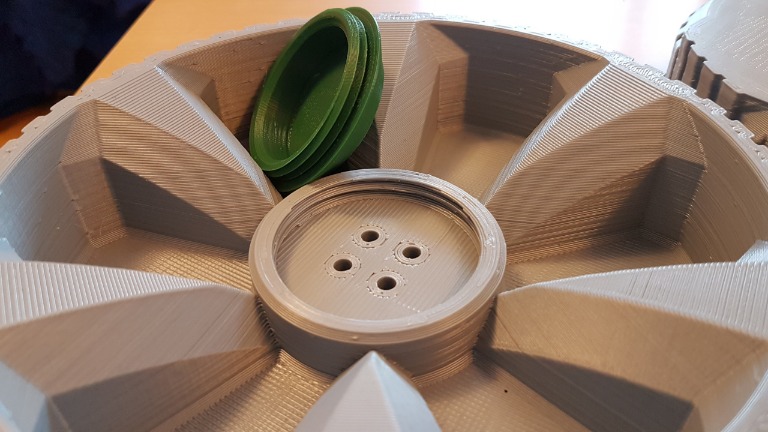

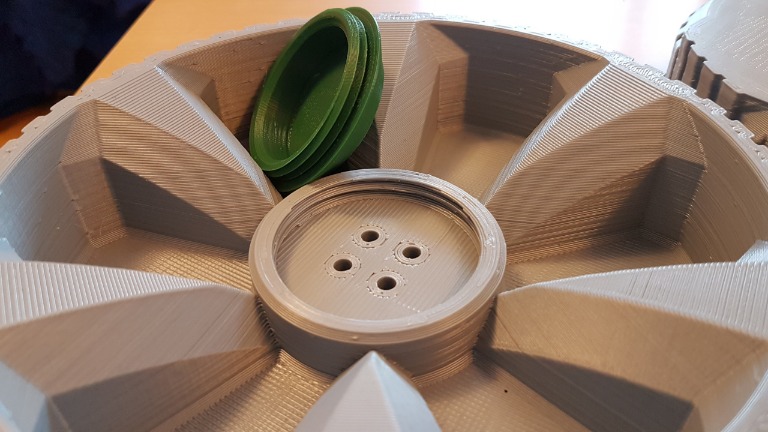

Rear wheels and wheel caps

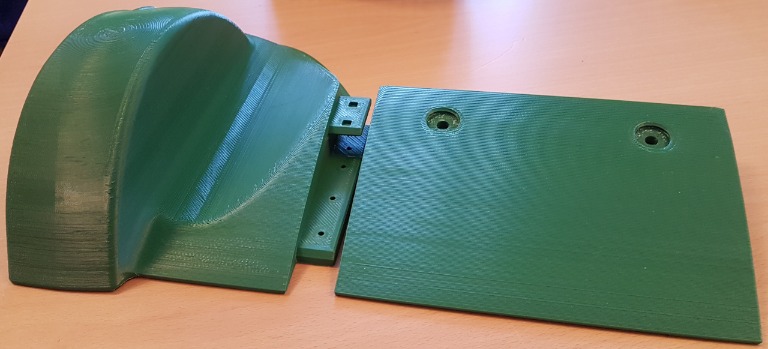

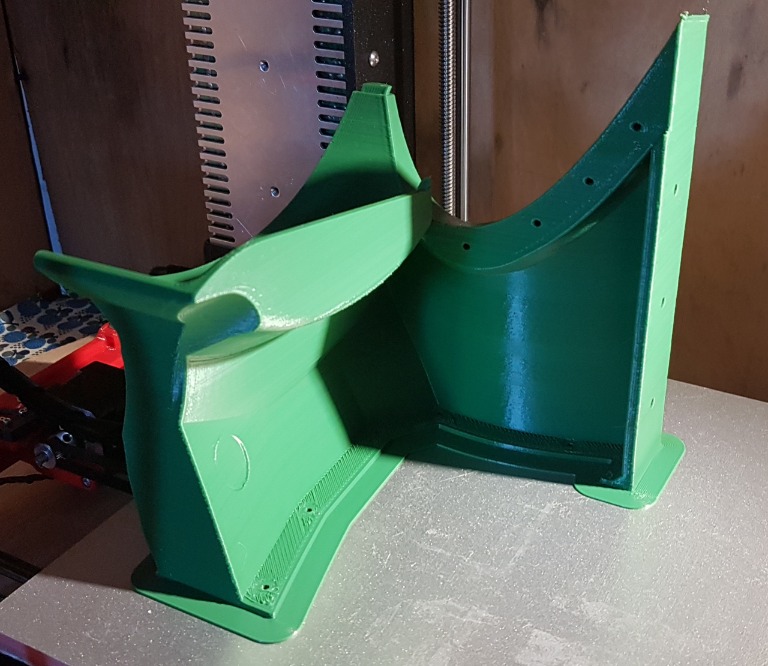

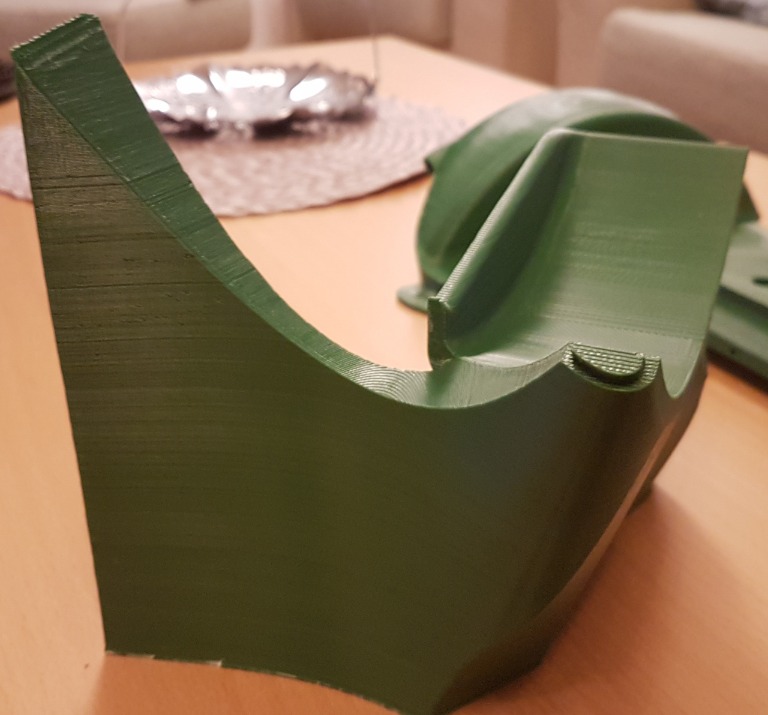

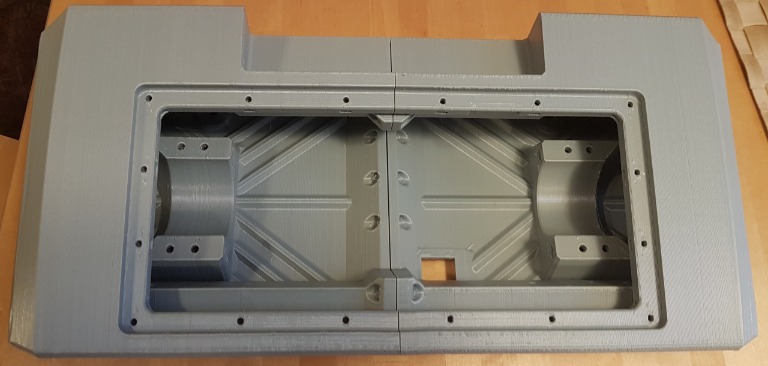

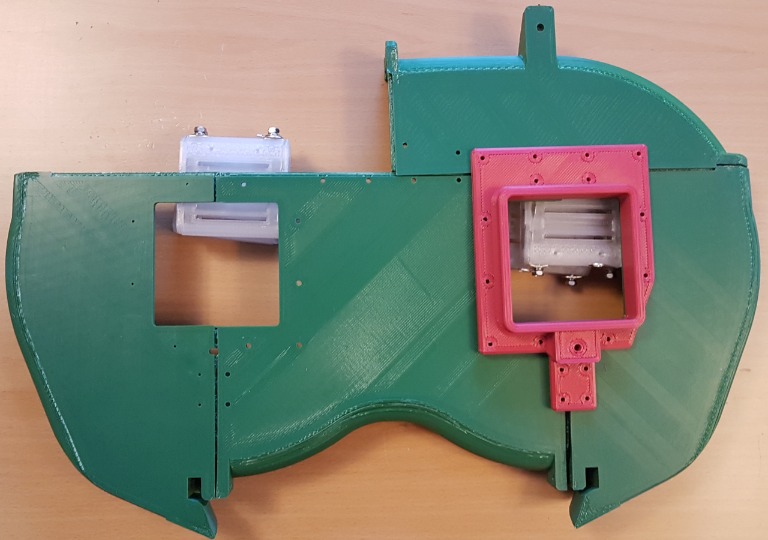

Cut cover almost ready

Some progress has been made. Electronics kit has not arrived yet.

Battery box and NESE modules for 18650 cells. Plan is use samsung 35E 3500mAh cells (3p7s)

Front wheel assembly and perimeter receiver box

pcb box brackets and mowing motor brackets

Rear wheels and wheel caps

Cut cover almost ready