paddy

Active member

Hi,

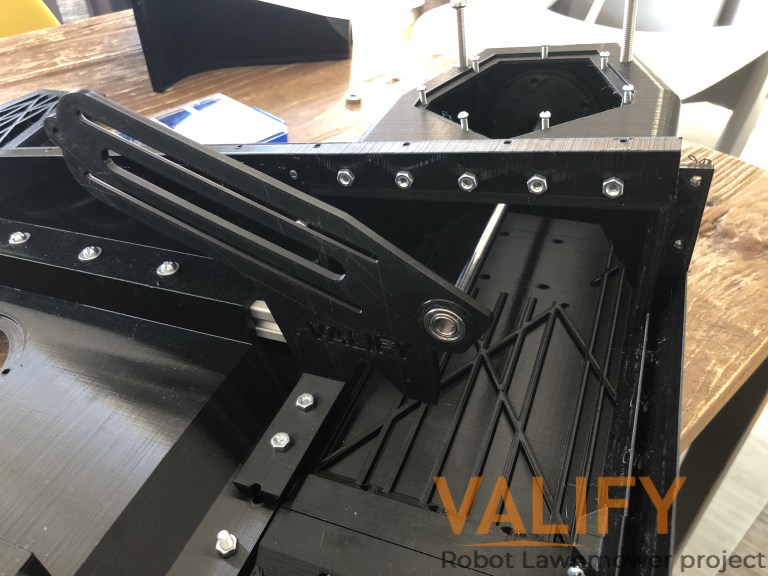

your progress looks great. How do you plan to get your parts rain proof? There seems to be no kind of seal between your parts. I'm not sure if this will become a problem because the parts are compressed together by screws and I assume you won't take the robot with you when diving.

your progress looks great. How do you plan to get your parts rain proof? There seems to be no kind of seal between your parts. I'm not sure if this will become a problem because the parts are compressed together by screws and I assume you won't take the robot with you when diving.