set the 'timed-out below smag' to very low.

it is becaus your smag is going to be close to 0 when you are directly on top of the cable.

Congratulation. What have you changed?

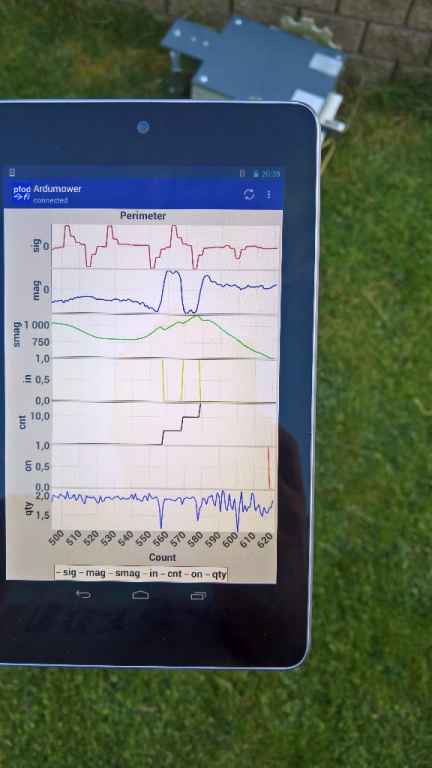

I just see that is 0... check your perimeter plots while tracking.

please also set the transition timeout to 10000.

Possible you don't have any transition for 2 sec

Now I remember the timed-out below smag has to be taken out of the code in robot.cpp for the STATE_PERI_TRACK:

that should be on the 1st change list

it is becaus your smag is going to be close to 0 when you are directly on top of the cable.

Congratulation. What have you changed?

I just see that is 0... check your perimeter plots while tracking.

please also set the transition timeout to 10000.

Possible you don't have any transition for 2 sec

Now I remember the timed-out below smag has to be taken out of the code in robot.cpp for the STATE_PERI_TRACK:

Code:

if (perimeter.signalTimedOut(0)) {

if ( (stateCurr != STATE_OFF) && (stateCurr != STATE_MANUAL) && (stateCurr != STATE_STATION)

&& (stateCurr != STATE_STATION_CHARGING) && (stateCurr != STATE_STATION_CHECK)

&& (stateCurr != STATE_STATION_REV) && (stateCurr != STATE_STATION_ROLL)

&& (stateCurr != STATE_STATION_FORW) && (stateCurr != STATE_REMOTE) && (stateCurr != STATE_PERI_OUT_FORW)

&& (stateCurr != STATE_PERI_OUT_REV) && (stateCurr != STATE_PERI_OUT_ROLL) && (stateCurr != STATE_PERI_TRACK)) {

Console.println("Error: perimeter too far away");

addErrorCounter(ERR_PERIMETER_TIMEOUT);

setNextState(STATE_ERROR,0);that should be on the 1st change list