So, Recently, I was asked to design a concept chassis for the Ardumower and the aim of this concept was the ability to print the entire chassis in a 20x20x20 3D printer.

The design is about 90% complete + revision after the first completed chassis has been printed.

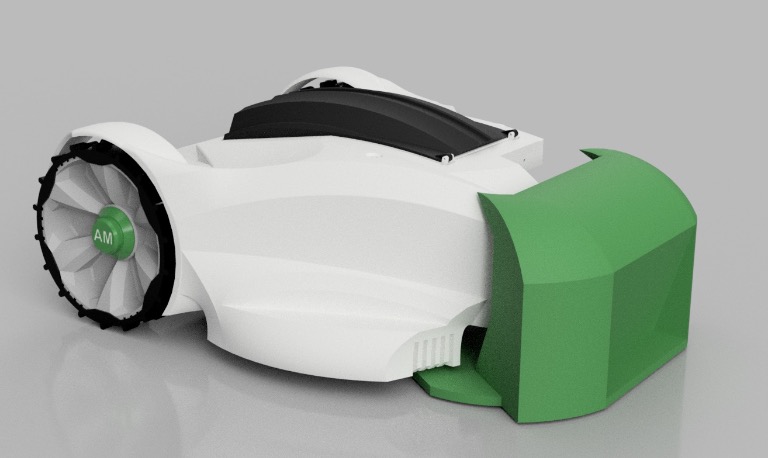

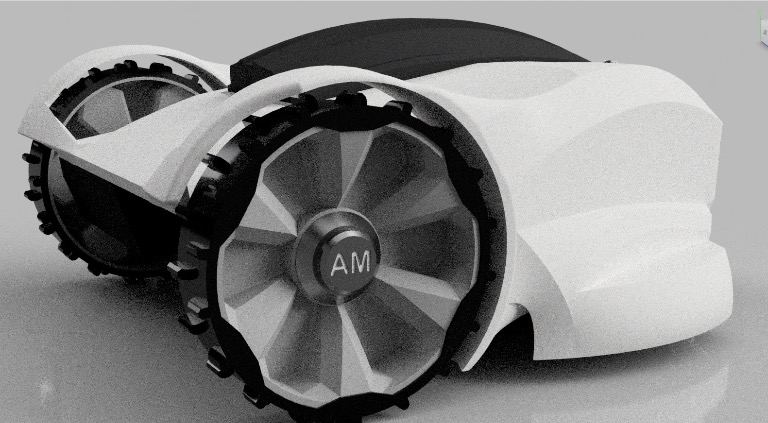

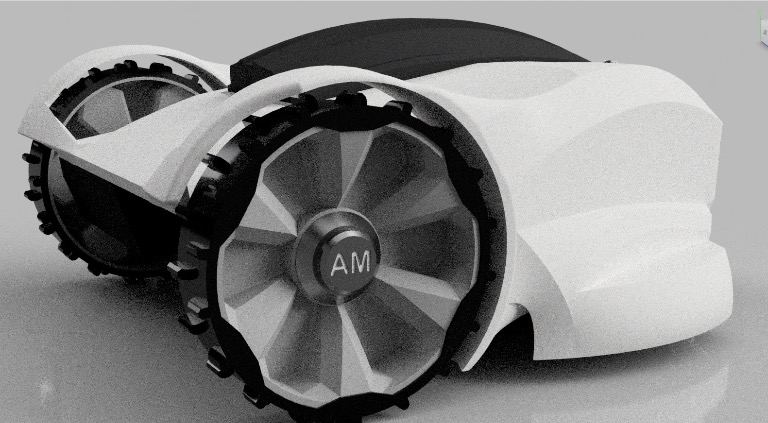

So here is some concept photos of the chassis:

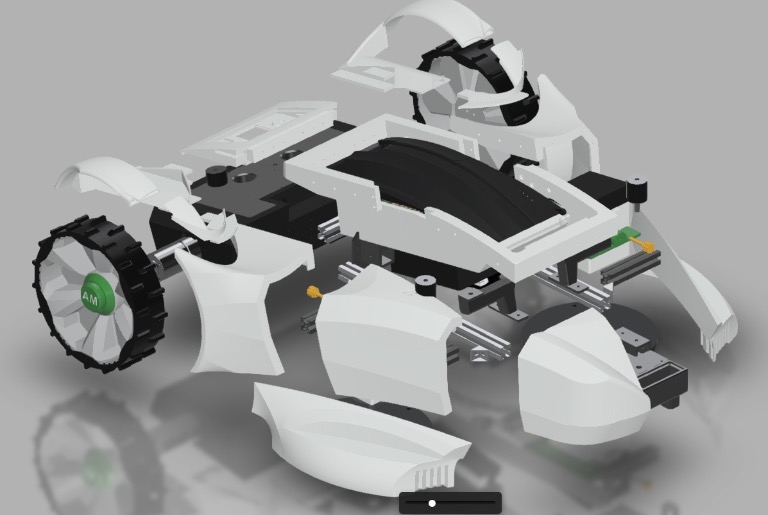

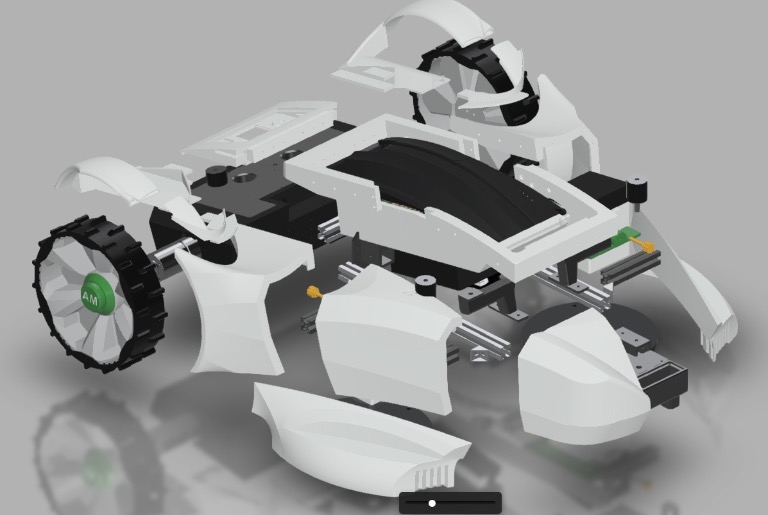

exploded view:

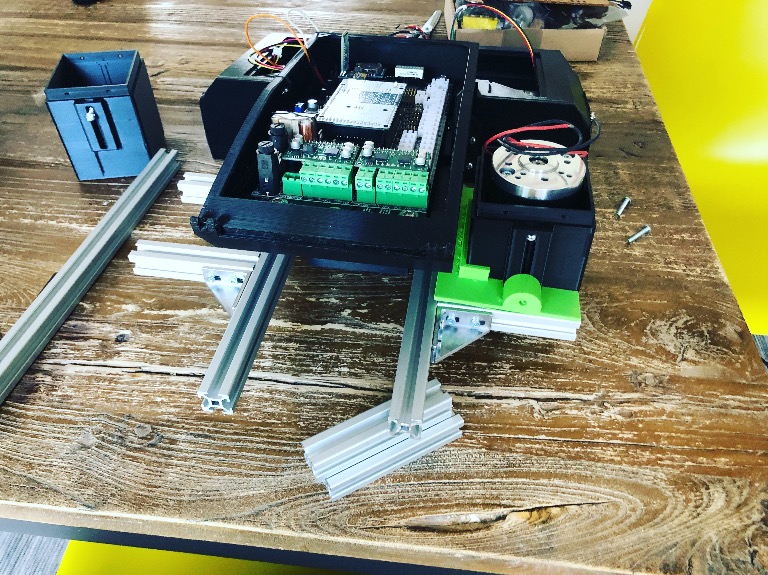

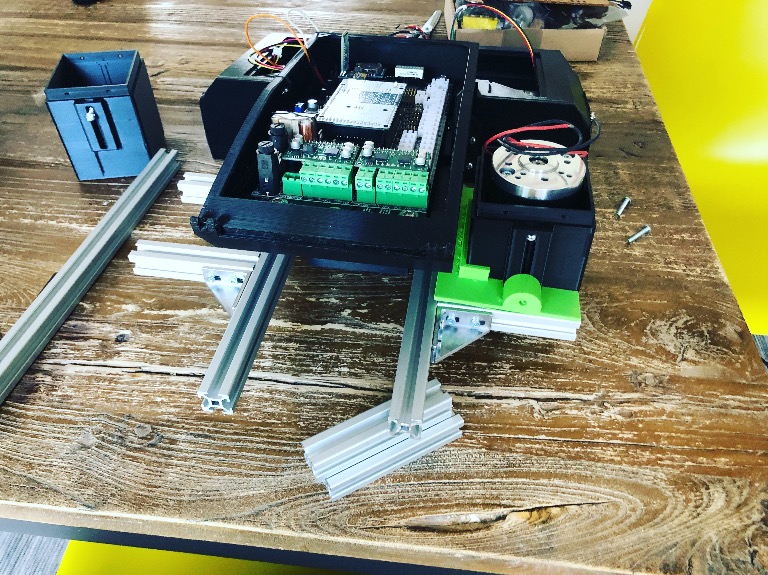

Some images from current status of the construction:

The design is about 90% complete + revision after the first completed chassis has been printed.

So here is some concept photos of the chassis:

exploded view:

Some images from current status of the construction: