Today I placed 100m of perimeter wire. Measured resistence is 2ohm, so I used also 10ohm 50w resistor.

So I have 12V and 12ohm = 1A

Question is, if it's normal that resistor is very hot (you can't touch) when sender is running ?

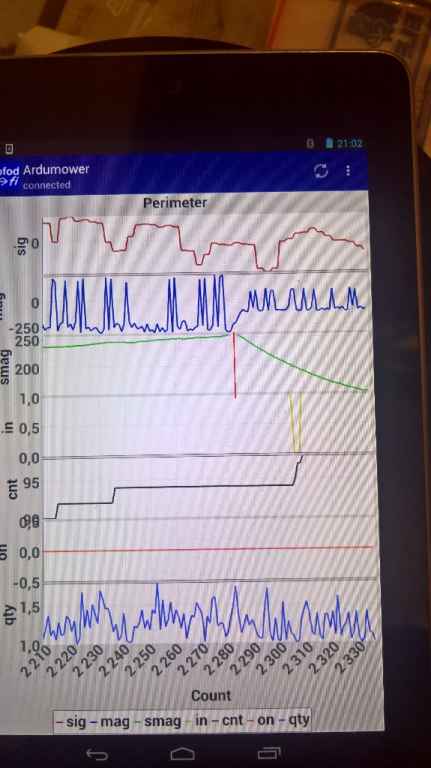

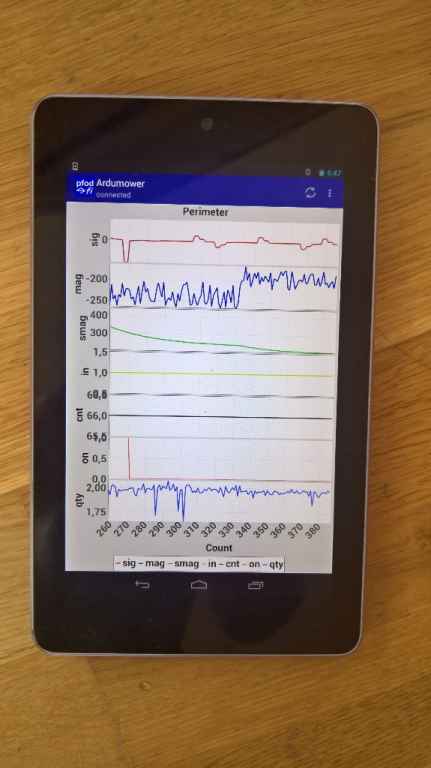

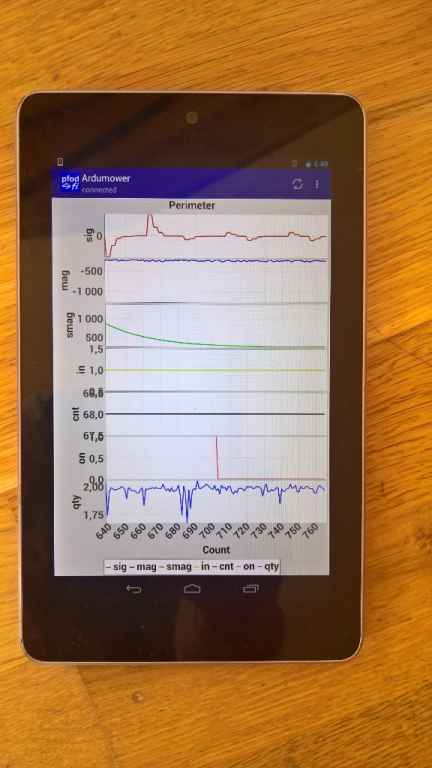

When I go manually (by hand, motors off) with mower inside/outside, position is good detected, but when I start a motors, detection isn't working correctly.

It looks like there is a big noise from the motors. Is there any possibility how to decrease noise ? I know bigger distance from the motor is a solution, but any other like metal shield and etc ....

Thank you

Alex

So I have 12V and 12ohm = 1A

Question is, if it's normal that resistor is very hot (you can't touch) when sender is running ?

When I go manually (by hand, motors off) with mower inside/outside, position is good detected, but when I start a motors, detection isn't working correctly.

It looks like there is a big noise from the motors. Is there any possibility how to decrease noise ? I know bigger distance from the motor is a solution, but any other like metal shield and etc ....

Thank you

Alex