Lighthouse

Member

Hallo Zusammen,

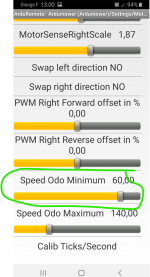

Als ich von dem Ardumower gehört habe, war ich sofort Feuer und Flamme und bin sofort mit der Planung angefangen. Durch die aktuellen Lieferengpässe habe ich mich entschlossen, die Platine nachzubauen und konnte so auch das Gehäuse schmaler bauen. Ich habe jetzt einen Radstand von 28,5cm, Antrieb hinten und eine Lenkrolle vorn im Abstand von 45cm zur Hinterachse. Damit benötigt er zum Drehen etwas Drehmoment da er so schmal und lang ist. Das ist auch schon mein Problem. Ich hatte Azurit getestet und die Einstellungen soweit gemacht, dass er gut lief und auch drehte. Gern wollte ich aber in Bahnen fahren und habe Aruritber geflasht. Soweit funktioniert alles, keine Fehler. Versuche ich im Modus Lanes zu starten, fängt er an zu drehen (Kalibrieren?), kommt aber nicht bis zum Ende der Drehung. Er bleibt pfeifend(PWM) stehen. Wenn ich ihn anheben, drehen die Räder langsam aber kraftlos. Ich bin auf der Suche nach einer Einstellung wie MinOdoPWM für alle Bewegungen, sodass er bei langsamer Geschwindigkeit nicht stehen bleibt. Besser noch eine Regelung der Drehzahl mit Hilfe der Odometrie. Die vorhandenen Parameter p und i habe ich schon ohne Erfolg verändert. Würde es Sinn machen, im <Driver> dem Speed eine Untergrenze über zu bügeln? Hat jemand einen Tip für mich, warum die Motoren nicht (immer) anlaufen?

Verbaut sind Golf3 Scheibenwischermotoren und BTS7960 Treiber - also eigentlich Leistung im Überfluss. Die Kombi läuft auch sehr kraftvoll bei genügend PWM.

Danke

Jens

Als ich von dem Ardumower gehört habe, war ich sofort Feuer und Flamme und bin sofort mit der Planung angefangen. Durch die aktuellen Lieferengpässe habe ich mich entschlossen, die Platine nachzubauen und konnte so auch das Gehäuse schmaler bauen. Ich habe jetzt einen Radstand von 28,5cm, Antrieb hinten und eine Lenkrolle vorn im Abstand von 45cm zur Hinterachse. Damit benötigt er zum Drehen etwas Drehmoment da er so schmal und lang ist. Das ist auch schon mein Problem. Ich hatte Azurit getestet und die Einstellungen soweit gemacht, dass er gut lief und auch drehte. Gern wollte ich aber in Bahnen fahren und habe Aruritber geflasht. Soweit funktioniert alles, keine Fehler. Versuche ich im Modus Lanes zu starten, fängt er an zu drehen (Kalibrieren?), kommt aber nicht bis zum Ende der Drehung. Er bleibt pfeifend(PWM) stehen. Wenn ich ihn anheben, drehen die Räder langsam aber kraftlos. Ich bin auf der Suche nach einer Einstellung wie MinOdoPWM für alle Bewegungen, sodass er bei langsamer Geschwindigkeit nicht stehen bleibt. Besser noch eine Regelung der Drehzahl mit Hilfe der Odometrie. Die vorhandenen Parameter p und i habe ich schon ohne Erfolg verändert. Würde es Sinn machen, im <Driver> dem Speed eine Untergrenze über zu bügeln? Hat jemand einen Tip für mich, warum die Motoren nicht (immer) anlaufen?

Verbaut sind Golf3 Scheibenwischermotoren und BTS7960 Treiber - also eigentlich Leistung im Überfluss. Die Kombi läuft auch sehr kraftvoll bei genügend PWM.

Danke

Jens