sigismondi

Member

Dear All, I have two question to complete my PCB 0.5

1) Do I understand corretly? If I use ARDUINO DUE ----> Lp0-Lp15 must be open, as they are on PCB.

If I use ARDUINO MEGA ----> Lp0-Lp15 must be welded (short-circuit)

2) If I use ARDUINO DUE---> DC/DC 10V (must be used), DC/DC 3V (must be used)....DC/DC 5V (don't needed)

If I use ARDUINO MEGA---> DC/DC 10V (must be used), DC/DC 5V (must be used)....DC/DC 3V (must be used)

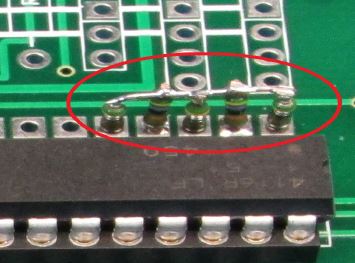

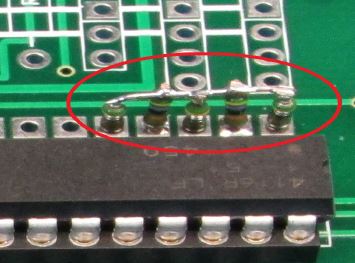

3) If I use arduino MEGA is it necessary pull-up odometry ad workaround (see attached)?? After modification I need to weld Lp0-Lp15??

thank you all

1) Do I understand corretly? If I use ARDUINO DUE ----> Lp0-Lp15 must be open, as they are on PCB.

If I use ARDUINO MEGA ----> Lp0-Lp15 must be welded (short-circuit)

2) If I use ARDUINO DUE---> DC/DC 10V (must be used), DC/DC 3V (must be used)....DC/DC 5V (don't needed)

If I use ARDUINO MEGA---> DC/DC 10V (must be used), DC/DC 5V (must be used)....DC/DC 3V (must be used)

3) If I use arduino MEGA is it necessary pull-up odometry ad workaround (see attached)?? After modification I need to weld Lp0-Lp15??

thank you all