Lighthouse

Member

Hallo,

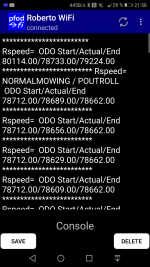

sobald mein Mäher zum Perimeterdraht kommt, stoppt er, fährt zurück und dreht (POUTROLL). Diese Drehung ist aber nicht wie erwartet zwischen 20 und 100° sondern meistens zwischen ca. 300 und 400°. Er fährt also gern zum Draht und dreht komplett um dann erneut zum Draht zu fahren. So dreht er minutenlang bis er dann doch wieder weniger weit dreht und weiter mäht. Ich habe im PERI_OUT_ROLL nach einem Fehler gesucht, doch seint hier alles OK. Die Drehung sollte im mower.cpp so begrentzt sein:

motorRollDegMax = 100; // max. roll Deg

motorRollDegMin = 20; //min. roll Deg

Im ODO-Test fährt er genau 3m gerade aus, doch bei der 180° Drehung stoppe er nicht und dreht und dreht.

Hat jemand eine Idee, wo ich suchen kann?

Danke

Jens

sobald mein Mäher zum Perimeterdraht kommt, stoppt er, fährt zurück und dreht (POUTROLL). Diese Drehung ist aber nicht wie erwartet zwischen 20 und 100° sondern meistens zwischen ca. 300 und 400°. Er fährt also gern zum Draht und dreht komplett um dann erneut zum Draht zu fahren. So dreht er minutenlang bis er dann doch wieder weniger weit dreht und weiter mäht. Ich habe im PERI_OUT_ROLL nach einem Fehler gesucht, doch seint hier alles OK. Die Drehung sollte im mower.cpp so begrentzt sein:

motorRollDegMax = 100; // max. roll Deg

motorRollDegMin = 20; //min. roll Deg

Im ODO-Test fährt er genau 3m gerade aus, doch bei der 180° Drehung stoppe er nicht und dreht und dreht.

Hat jemand eine Idee, wo ich suchen kann?

Danke

Jens