Hello everyone,

This is Milos from Bosnia, I already wrote to you in this thread when I was just starting to build my Ardumower.

I am currently very close to finishing it and I have some more questions for you guys. I didn't have time to write in the meantime, but once I finish my Ardumower I will make a very detailed post about my build experience and I plan to be active on the forums.

I currently have a problem with CHARGER ERROR.

Let me please first explain how I set up my mower so you can better understand what is going on and hopefully help me.

My Ardumower is powered by two lead (Pb) batteries connected in series (24V).

My charger is a simple DC power supply which doesn't do any kind of current sensing or battery management.

I want the Arduino to monitor the charging current and control the charging.

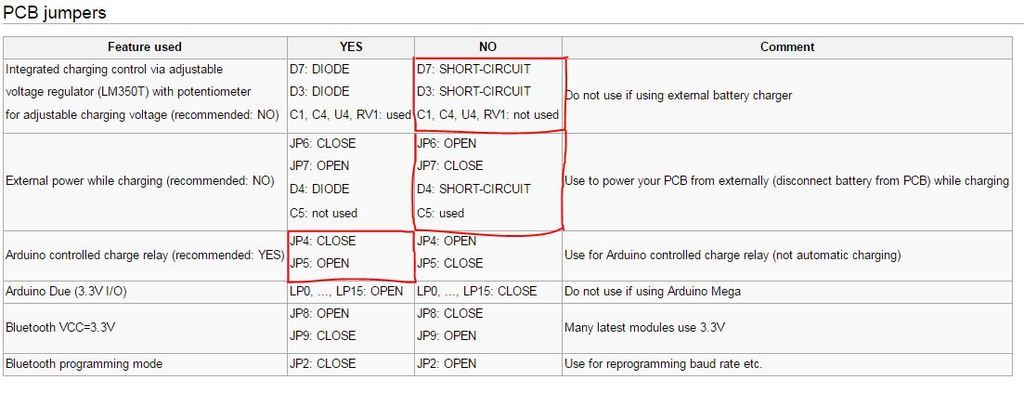

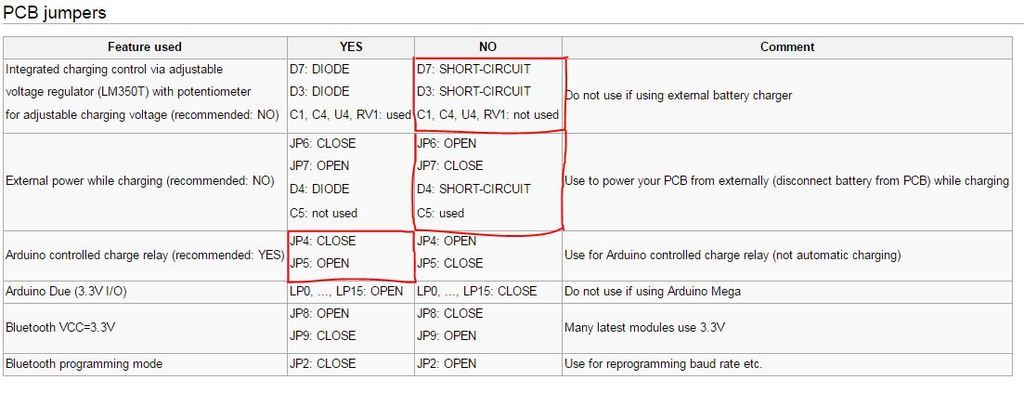

I set up the charging as described in wiki page, see this screenshot for details:

I have done everything that is circled in red:

D7 - installed and then short-circuit with a piece of wire

D3 - installed and then short-circuit with a piece of wire

C1, C4 - installed and then short-circuit with a piece of wire

U4, RV1 - not used, never installed

JP6 - Open

JP7 - Closed

D4 - Short-circuit

C5 - Used

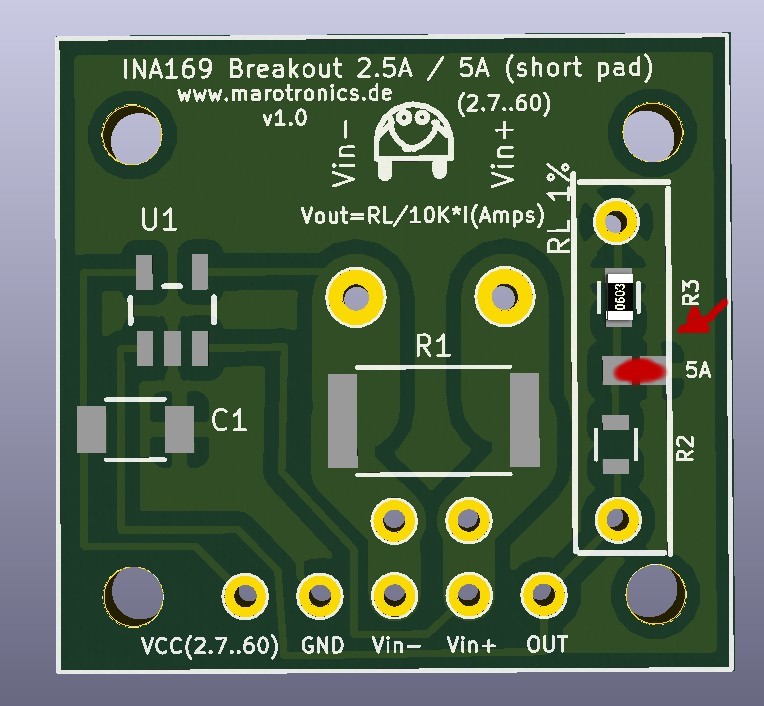

For the U5 I have ACS712 module connected instead of the INA169 module.

My batteries are connected to the board through the Battery connector (P43) and my charger contacts are connected through the Charger connector (P42).

The mower runs fine in manual mode but when I put it in Auto mode (via phone app), the wheels rotate a bit to the back (reverse) and state changes from OFF to STATION CHECK, and it waits for several seconds and then goes into error state (state is ERROR and robot beeps continuously). When I check the errors in the app, there is CHARGER error.

Even if I try to connect the charger to the charger connector, the same thing happens.

If I go to Settings -> Battery while the charger is not connected, it says (for example):

Charging voltage: 24.6 Charging current: 0.00 A

When I connect the charger, it shows the same thing, only this time the voltage is higher (it displays voltage a bit lower than the charger output voltage).

The relay never switches on/off.

Can you please tell me what is going on, why is it not detecting the charger properly?

Maybe my combination of diodes, capacitors and jumpers is not correct?

Thank you, any help is highly appreciated.

Milos

This is Milos from Bosnia, I already wrote to you in this thread when I was just starting to build my Ardumower.

I am currently very close to finishing it and I have some more questions for you guys. I didn't have time to write in the meantime, but once I finish my Ardumower I will make a very detailed post about my build experience and I plan to be active on the forums.

I currently have a problem with CHARGER ERROR.

Let me please first explain how I set up my mower so you can better understand what is going on and hopefully help me.

My Ardumower is powered by two lead (Pb) batteries connected in series (24V).

My charger is a simple DC power supply which doesn't do any kind of current sensing or battery management.

I want the Arduino to monitor the charging current and control the charging.

I set up the charging as described in wiki page, see this screenshot for details:

I have done everything that is circled in red:

D7 - installed and then short-circuit with a piece of wire

D3 - installed and then short-circuit with a piece of wire

C1, C4 - installed and then short-circuit with a piece of wire

U4, RV1 - not used, never installed

JP6 - Open

JP7 - Closed

D4 - Short-circuit

C5 - Used

For the U5 I have ACS712 module connected instead of the INA169 module.

My batteries are connected to the board through the Battery connector (P43) and my charger contacts are connected through the Charger connector (P42).

The mower runs fine in manual mode but when I put it in Auto mode (via phone app), the wheels rotate a bit to the back (reverse) and state changes from OFF to STATION CHECK, and it waits for several seconds and then goes into error state (state is ERROR and robot beeps continuously). When I check the errors in the app, there is CHARGER error.

Even if I try to connect the charger to the charger connector, the same thing happens.

If I go to Settings -> Battery while the charger is not connected, it says (for example):

Charging voltage: 24.6 Charging current: 0.00 A

When I connect the charger, it shows the same thing, only this time the voltage is higher (it displays voltage a bit lower than the charger output voltage).

The relay never switches on/off.

Can you please tell me what is going on, why is it not detecting the charger properly?

Maybe my combination of diodes, capacitors and jumpers is not correct?

Thank you, any help is highly appreciated.

Milos