max@birley_com

Member

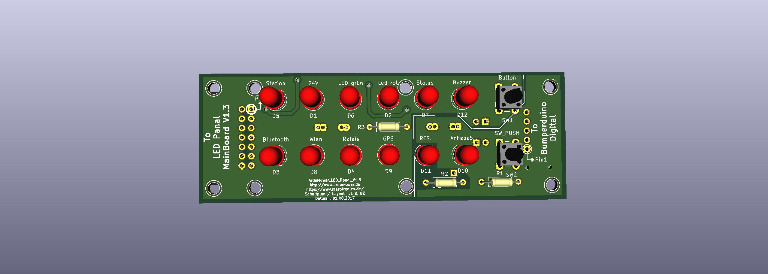

I just bought the 1.3 PCB board and waiting for it to arrive. I have reviewed some 1.2 building instructions however if someone can point me to the best (in English) building instructions for the 1.3 pub with pictures I would be really grateful

Also what is the benefit of using the Arduino Due over the Megga and is it fully implemented the code

regards

Also what is the benefit of using the Arduino Due over the Megga and is it fully implemented the code

regards