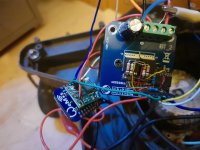

Hi, as "advertised", the mainboard of my 230ACX has failed beyond repairing; I like the Ardumower "no waste" philosophy and playing with electronics, so I'm considering a complete replacement of electronics of the robot reusing chassis, motors and docking station. Internally space should be enough to confortably house all components.

I don't know if I have to keep batteries, or at least the voltage (18V) to match motors specifications; the complication is this robot has two of them and switch between them as needed; I have no solution at the moment; so I can only try with one and and see how to improve.

The main proble is with motors: not wheel motors, 9-wires that would interface straight with DIY ArduMower Brushless Driver, but the mowing motor.

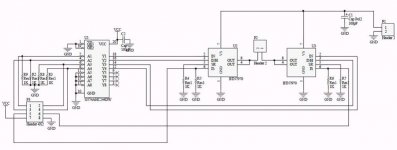

By looking at the original board (4 MOSFETs in H-bridge), I guess it is a single-coil, single-Hall-sensor motor. It makes sense: the blades rotate in random direction, only speed matters.

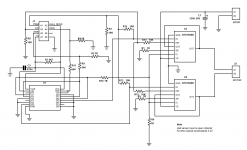

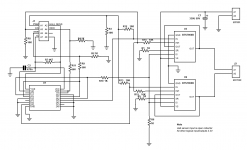

I cannot understand if DRV8308 is able to drive this kind of motor. I only can connect 2 wires to coils, the third would be unused. Datasheet states it has a 180° drive mode, but it starts in 120° mode then switches to 180° when reaching a configurable speed; I could set an extremely low threshold so it would just start and immediately switch, but it seems in 180° mode waveforms are still over three phases.

Does anybody have experience in such a setup?

Alternatively I could replace the whole motor, but apart from the cost and the throwing away a perfectly fit one, I'm scared of the needed mechanical adaptation to fit a different one...

I don't know if I have to keep batteries, or at least the voltage (18V) to match motors specifications; the complication is this robot has two of them and switch between them as needed; I have no solution at the moment; so I can only try with one and and see how to improve.

The main proble is with motors: not wheel motors, 9-wires that would interface straight with DIY ArduMower Brushless Driver, but the mowing motor.

By looking at the original board (4 MOSFETs in H-bridge), I guess it is a single-coil, single-Hall-sensor motor. It makes sense: the blades rotate in random direction, only speed matters.

I cannot understand if DRV8308 is able to drive this kind of motor. I only can connect 2 wires to coils, the third would be unused. Datasheet states it has a 180° drive mode, but it starts in 120° mode then switches to 180° when reaching a configurable speed; I could set an extremely low threshold so it would just start and immediately switch, but it seems in 180° mode waveforms are still over three phases.

Does anybody have experience in such a setup?

Alternatively I could replace the whole motor, but apart from the cost and the throwing away a perfectly fit one, I'm scared of the needed mechanical adaptation to fit a different one...