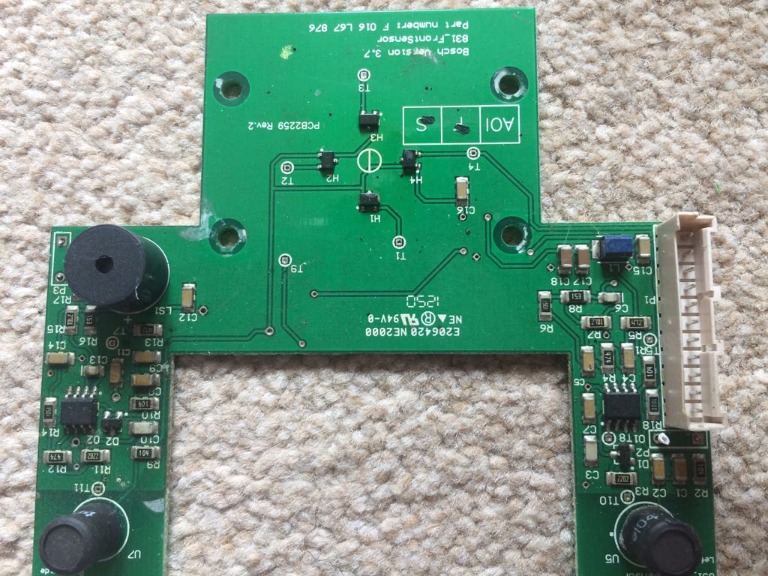

Hi all, just want say a massive thanks for this project. The information here is amazing and it's been fun hacking a Bosch Indego into an Ardumower!

I may well have set up my perimeter wrong, but I'm getting a fair amount of heat from the power resister (4.7ohms, possibly need more here) in the loop. The current pull is around 0.1 amps and the potentiometer is maybe at 50%.

Something that the Bosch mower did was send a signal for 8ms and then switch off for 92ms. I've done a little testing here to see what difference it made to the sender and using this approach brought the current down to 0.08 amps and the power resister barely warms up.

What I'm now having problems with is getting the mower to recognise the new signal, I don't fully understand the code here yet.

Has anyone tried this approach before or think it might work?

Also, instead of using current detection to know if the mower is in the station, I'm re-using the Bosch's magnetic reed sensor. It seems like a more robust solution.

Cheers

Tom

I may well have set up my perimeter wrong, but I'm getting a fair amount of heat from the power resister (4.7ohms, possibly need more here) in the loop. The current pull is around 0.1 amps and the potentiometer is maybe at 50%.

Something that the Bosch mower did was send a signal for 8ms and then switch off for 92ms. I've done a little testing here to see what difference it made to the sender and using this approach brought the current down to 0.08 amps and the power resister barely warms up.

What I'm now having problems with is getting the mower to recognise the new signal, I don't fully understand the code here yet.

Has anyone tried this approach before or think it might work?

Also, instead of using current detection to know if the mower is in the station, I'm re-using the Bosch's magnetic reed sensor. It seems like a more robust solution.

Cheers

Tom