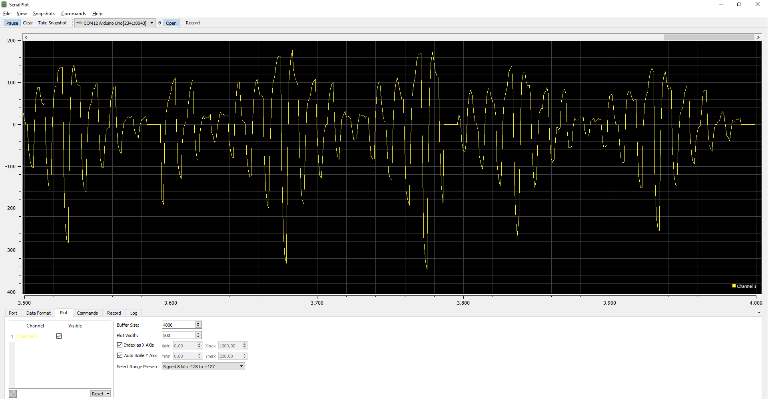

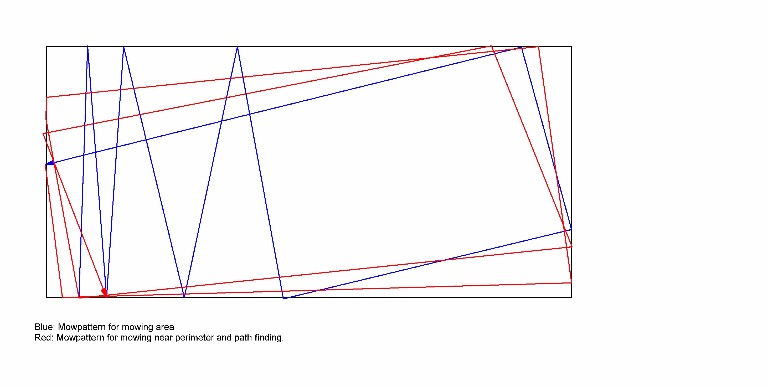

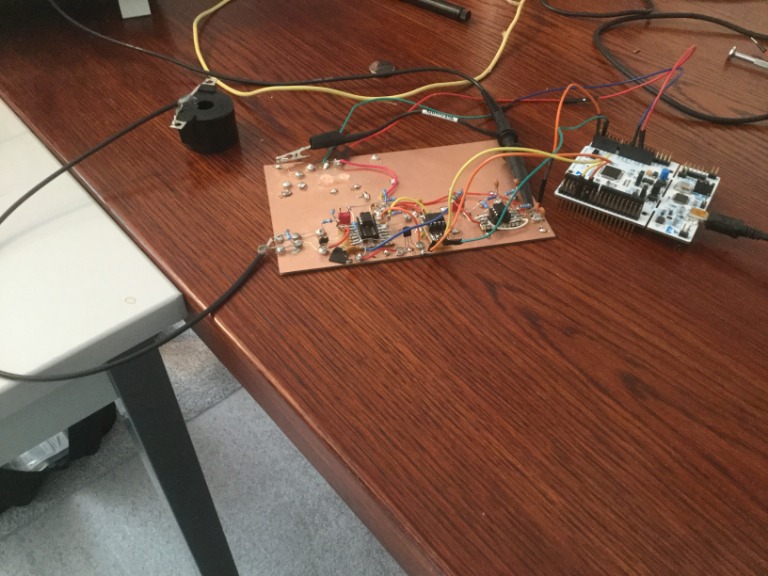

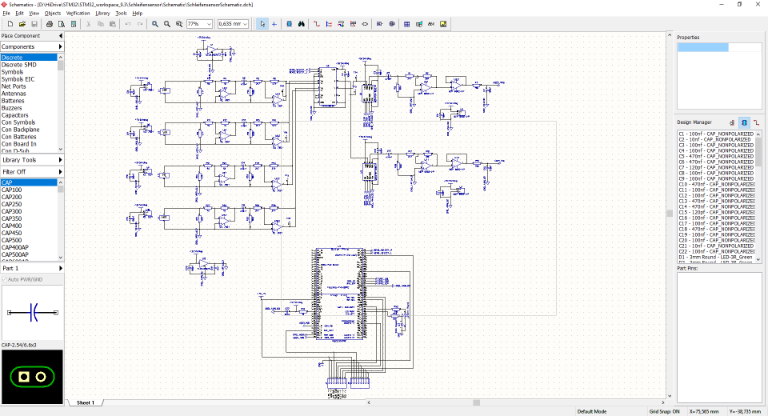

Hi, in order I just programmed the new perimeter recognition routine in my Raindancer firmware I decided to do a tutorial about how the perimeter recognition works. I used the english language in order there are a lot of people who don't speak german. But I speak english maybe 3 times a year and this was really a challenge and you will hear it :lol:

Today I recorded the videos about the theoretical part. Not really perfect and because I don't earn any money with that it must not be perfect. But I hope it helps people to understand the function of the perimeter recognition.

Before I start the practical part, it would be nice if some people can can take a look to the videos and give me feedback if you understand what I say and what I want to explain. Hopefullly it is not too boring. I have to speak very slowly

https://youtu.be/0vkl8GalbNs https://youtu.be/UNVP10kjyu4 https://youtu.be/GwQHI8PqVIc https://youtu.be/TMDxJuEJg8w

https://youtu.be/yFnyuTg41mE

Today I recorded the videos about the theoretical part. Not really perfect and because I don't earn any money with that it must not be perfect. But I hope it helps people to understand the function of the perimeter recognition.

Before I start the practical part, it would be nice if some people can can take a look to the videos and give me feedback if you understand what I say and what I want to explain. Hopefullly it is not too boring. I have to speak very slowly

https://youtu.be/0vkl8GalbNs https://youtu.be/UNVP10kjyu4 https://youtu.be/GwQHI8PqVIc https://youtu.be/TMDxJuEJg8w

https://youtu.be/yFnyuTg41mE