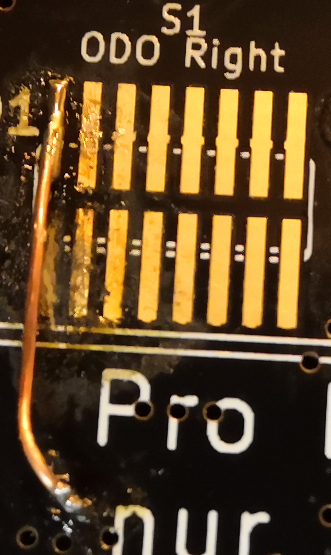

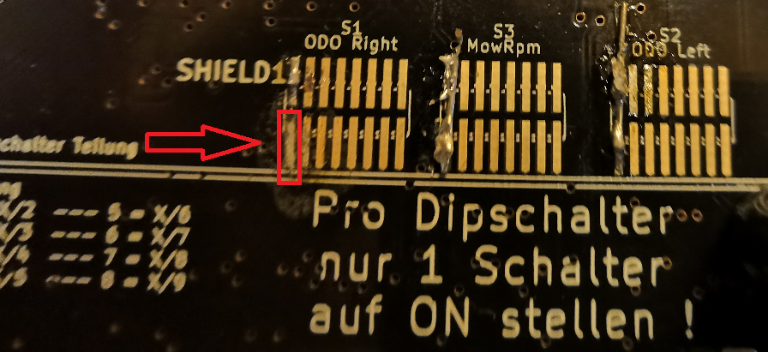

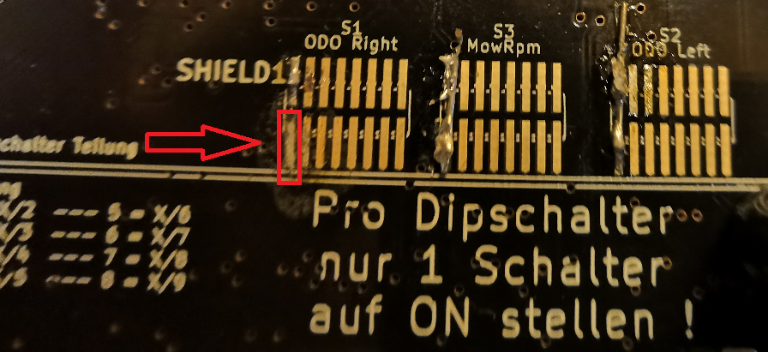

I'm putting up my second unit now and I just made a total mess of the dips soldering. S2 and S3 are ok, but while soldering the S1 I managed to connect adjacent pins and while desoldering and resoldering the lower pin contact eventually came totally off. The pin I'm talking is the one inside the red box in the picture, there really is nothing but motherboard plastic left even if it looks there is the contact still.

So what are my options:

1. Can I do a jump wire somewhere? If so, how? I was looking at schematics, but couldn't really figure out what mapped to what on the chips on otherside of pcb.

2. Or should I just try remove all the solderings and use the 3rd pins? It says it's x/4 divider, but what does that really mean? Can it be easily changed within the code? Should I use the x/4 only for drive motors or for the mower motor too? The only thing I can find in the code is the below. I'm afraid there might be something else hardcoded around..

3. What else?

So what are my options:

1. Can I do a jump wire somewhere? If so, how? I was looking at schematics, but couldn't really figure out what mapped to what on the chips on otherside of pcb.

2. Or should I just try remove all the solderings and use the 3rd pins? It says it's x/4 divider, but what does that really mean? Can it be easily changed within the code? Should I use the x/4 only for drive motors or for the mower motor too? The only thing I can find in the code is the below. I'm afraid there might be something else hardcoded around..

Code:

#define DIVIDER_DIP_SWITCH 2 // sets used PCB odometry divider (2=DIV/2, 4=DIV/4, 8=DIV/8, etc.)

odometryTicksPerRevolution /= DIVIDER_DIP_SWITCH; // encoder ticks per one full resolution3. What else?