Hi,

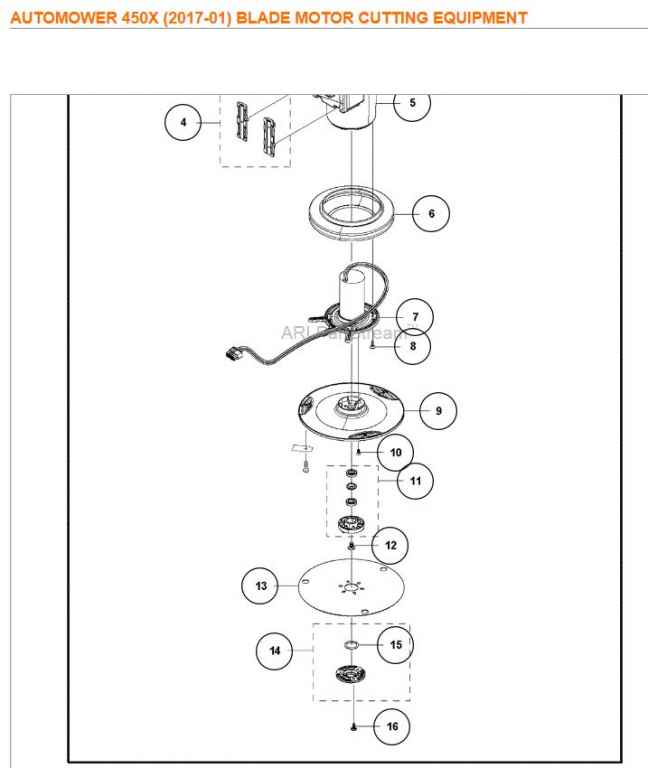

mower is running, but still working on improvements. From the mechanical side I see a problem in cutting disc and blades.

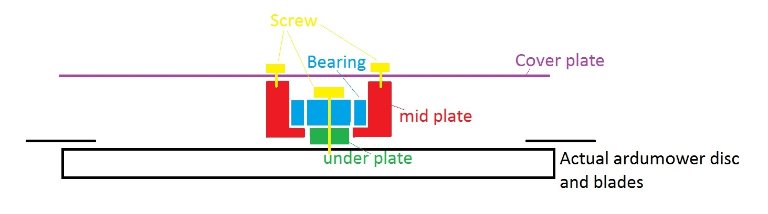

Very often blades stop turning around screw axis, because there is a grass between blades and disc :

Grass on the blade :

Side view:

Do you have a similar problems? What's your solution? Blade position (upper/lower side of disc) ?

Thanks for feedback

Alex

mower is running, but still working on improvements. From the mechanical side I see a problem in cutting disc and blades.

Very often blades stop turning around screw axis, because there is a grass between blades and disc :

Grass on the blade :

Side view:

Do you have a similar problems? What's your solution? Blade position (upper/lower side of disc) ?

Thanks for feedback

Alex